Package Bottle Water Project in Bangladesh

Package Bottle Water Project

Jar Water Plant in Bangladesh is most booming business now days. The demand of pure drinking water is increasing year after year. The average per capita consumption of pure drinking water has increased and given the limited resource of fresh water it is difficult for the countries to make available its population the fresh water. The crisis of pure drinking water in Bangladesh, keeping this situation in mind many industries and individual personnel have set up mineral water plant / Jar Water Project / Drinking Water Pant in order to obtain fresh pure drinking water. We appreciate those initiator and ready to help them to choose the right water treatment process based on the Comprehensive water analysis report and best equipment and machineries.

All Water Treatment Plants are designed as per “WHO and BSTI” guidelines, recommended International code of Hygienic practice for the collecting, processing, and marketing of Packaged Drinking Water/Natural Mineral Waters / Pure Drinking and confirm to the Standards set by our expertise for Mineral Water. We proudly introduce ourselves as Water Treatment Company catering to the need of turnkey projects in Packaged Drinking/Mineral Water Plants in Bangladesh. It is also available to us Pet Pre-form Machine in Bangladesh, Blow Molding Machines in Bangladesh, and Automatic Rinsing, Filling, and Capping Machines in Bangladesh, Pet Soda and Soda Filling machines in Bangladesh. We can give you all the machinery on complete Turnkey basis excluding Civil and Electromechanical Works.

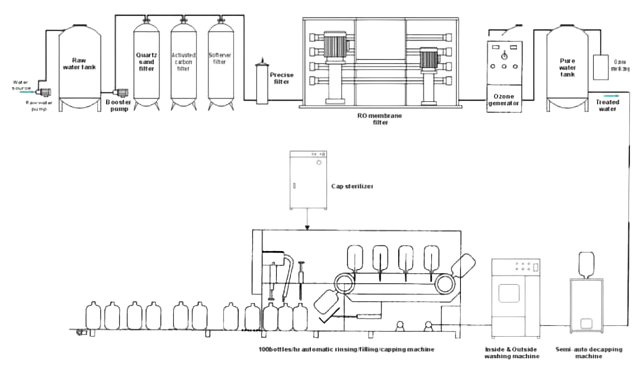

Process of Bottle Water Plant

Pre-Treatment – Pretreatment is most important part of Reverse Osmosis System, The life of reverse Osmosis Membrane depend on Pretreatment. In a reverse osmosis contact pre-treatment refers to the various physical and chemical water treatment processes that take place upstream of the reverse osmosis plant. The typical Pre-treatment usually includes the Multi-grade Filter, Pressure Sand Filter, Granular Activated Carbon Filter and Water Softener. But Pre Treatment depends on source water quality. To design perfect Pretreatment it must require to raw water analysis which are available to Meem Water Technology Laboratory

RO System-The application of reverse osmosis to the solution of problems in water treatment requires an understanding of the basic mechanisms involved in the process, the limitations of reverse osmosis and the pre-treatment requirements. Reverse Osmosis (RO) is the process in which water is forced by pressure through a semi-permeable membrane. Water passes through the membrane while the dissolved and particulate materials are left behind. When pressure is applied to the concentrated solution, water is forced through the membrane from the concentrated side to the diluted side. The spiral membrane is constructed of one or more membrane envelopes wound around a perforated central tube. The permeate (product water) passes through the membrane into the envelope and spirals inward to the central tube for collection. Reverse Osmosis utilizes the unique properties of a semi-permeable membrane to allow fluid to pass while restricting the flow of dissolved ionic material. With pressure applied to impure water on the side of such membrane materials, pure water will pass through, leaving most of the impurities behind. The rejection of the dissolved ionic material is a function of both molecular weight and ionic charge. For example, we can expect a nominal 90% rejection of sodium chloride, which means that the product water passing through the membrane will have a concentration of salt approximately one-tenth that of the feed water. The rejection of calcium carbonate (hardness) will be near 95%, while most metallic salts will be rejected at a rate of approximately 98% to 99%. The rejection of non-ionic or organic material is primarily by mechanical filtration. Most substances with a molecular weight of over 100 will be completely rejected by an intact reverse osmosis membrane. Low molecular weight organics, such as formaldehyde or phenol, can pass freely through an R.O. membrane, as can most dissolved gasses. Oil, suspended solids and particulate matter are mechanically filtered, as are viruses, bacteria, pyrogen, and larger organic molecules. To carry the rejected material away from the membrane surface, the feed side of the R.O. membrane is continually flushed with an excess flow, usually two to five times the product flow. This avoids clogging of the membrane surface and reduces the tendency toward scale formation.

Ozonize – Ozone is a high energy and very unstable molecule composed of three oxygen atoms (O3). The extra atom of oxygen attempts to recombine any things in its path in order to stabilize. When it comes in contact with contaminants such as Bacteria, Virus, or Organic Waste Materials Ozone acts as an oxidizer. Ozone is the strongest oxidizer commercially available. Ozone is produce from lightning bolts during an electric storm. The electric discharge disassociates the oxygen molecule in the air. The fresh smell that is present after a thunderstorm is a proof that Mother Nature is purifying the air. Ultraviolet rays from the sun react with oxygen in our atmosphere to form our protective ozone layer. We duplicated these process using charged electrodes. When the air we breathe which contains 21% oxygen, is passed thorough the ozonator, the oxygen in air is converted to ozone.

UV System- Ultraviolet rays have shorter wavelengths than visible light. A wavelength, the distance between the crests of two waves, is often measured in units called nanometers. A nanometer (nm) is a billionth of a meter, or about 1/25,000,000 inch. Wavelengths of visible light range from about 400 to 700 nm. Ultraviolet wavelengths range from about 1 to 400 nm and are beyond the range of visible light.The UV Germicidal Bulb is similar in design to a normal fluorescent bulb. It is a 4-pin ceramic base bulb with Teflon wiring. It is constructed of type “L”, hard glass quartz which eliminates ozone production. Heat output is low, allowing the UV lamp to be installed safely in several different positions. It can therefore fit into a wide variety of locations within the HVAC system

Automatic Washing Filling and Capping

Our Microcomputer Automatic Filling Machine is special equipment for filling pure water, also can be used for distilled water, mineral water and other sterile liquid filling machine. This equipment can washing, filling, put cover, pressure cover and transport finished product out of the machine, raw materials follow with food and other industries STD. The equipment adopts 380V (220V), 50HZ AC Power, which the machine have reliable performance, easy operation and simple maintenance PLC system and pneumatic control system. Completely conform to the hygiene standards, such as wash bottles, filling water, put cover, pressure cover process in the closed equipment, x and its effectively preventing water occur secondary pollution in filling process.

Typical Application of Reverse Osmosis Plant

Jar Water Project

Small Bottle Water Project

Boiler Feed Water Treatment

Food and Beverage Industry

Pharmaceutical Industry

Drinking Water Plant

How much is the investment ?

The investment of Jar Water Project / Drinking Water Project justly depends upon the type of plant, the Capacity of plant, Origin of Equipment and Source of Raw Water. Let us know your details requirement and we must help you to calculate the total investment and Let me explain this in details .For Jar Water Project in Bangladesh some people may look at a prosperous Jar Market, at the same time some other may feel that they should go for bottles, jars & Pouches. Some of you may feel that they will start with just bottle filling. Empty Bottles bought out where as some will want to have complete bottle making set as well.

So the final decision of “ Which type of Plant” Truly depends upon your targeted Market segments. Once you decide what to have in your product mix and source of water, you can decide the machinery and other things. Buy the Training Course to get an idea of how to decide the plant Capacity. Now to arrive at the Mineral Water Plant Cost, These are the elements which are combined each other.

Machinery & Equipment: All machines like Water Treatment Plant, Jar Filling Line, Laboratories equipment etc. will come under this.

Utilities: Water Consumption, air Compressor etc.

BSTI License & other Government License of Bangladesh expenditure.

Building Cost: Construction, interior cost as per your requirement.

Consultancy Charges: Free of cost from our end

About Us

Roopokar Trade Center !

It has professionally qualified & Experienced Engineering team. The Company under takes consultancy on total implement turnkey project consisting of design, Engineering Manufacturing, Installation & Troubleshooting of textile machinery, Boilre etc. We are capable of conducting business in large volumes as per best Quality products at very competitive price. We always focus on the investment and upgrading technology manufacturing, expansion, raising Quality products.

Get In Touch

Hey, We are looking Forward to start a project with You !

We are sole distributor of Doshion Veolia Resin, India (A Complete Water Solution). We are engaged in this manufacturing successfully all over Bangladesh turn since 27 years. After all we are very interested about every new plan and work with successfully completion, installation and Commission.